Technology / Voyager®

Voyager®

Pipeline Internal

Inspection Device

We develop innovation technology for pipeline inspection.

In the operation of long-distance pipeline fluid transport systems, monitoring the state inside is not a trivial task, but is an essential one.

Current technologies for assessing the internal integrity of pipelines require systems to be available for long periods and are often costly.

In pipelines with internal coatings (PU – Polyurethane, HDPE – High Density Polyethylene and others), PIGs instrumented by MFL – Magnetic Flux Leakage.

What is the Voyager® Probe?

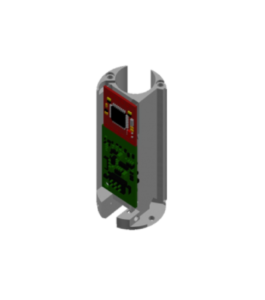

It is a miniaturized device, with the aim of determining the possible physical condition of the pipe internals.

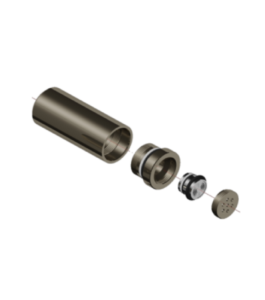

Both the Voyager® Probe electronics and sensors are arranged in a plastic housing, which in turn is inserted inside a grade 2 titanium capsule.

Sensors

TYPE OF DETECTED ABNORMALITIES

Inspection Results with the Voyager® Probe

DISCOVER MORE

Get in touch with BRASS and learn about everything we can build together.