Technology / Discrete Event Modeling

Discrete Event Modeling

Discrete event modeling is a tool that allows for the simulation of a real or projected system to evaluate behavior and performance over a specific time period under different operational scenarios.

Simulation of real project systems are used to evaluate behaviors under different operational scenarios.

Through this simulation tool, it is possible to model industrial processes to analyze how the system would behave under different production scenarios, increased failure rates, changes in equipment availability, etc.

Some key features include:

Case of application of discrete event modeling

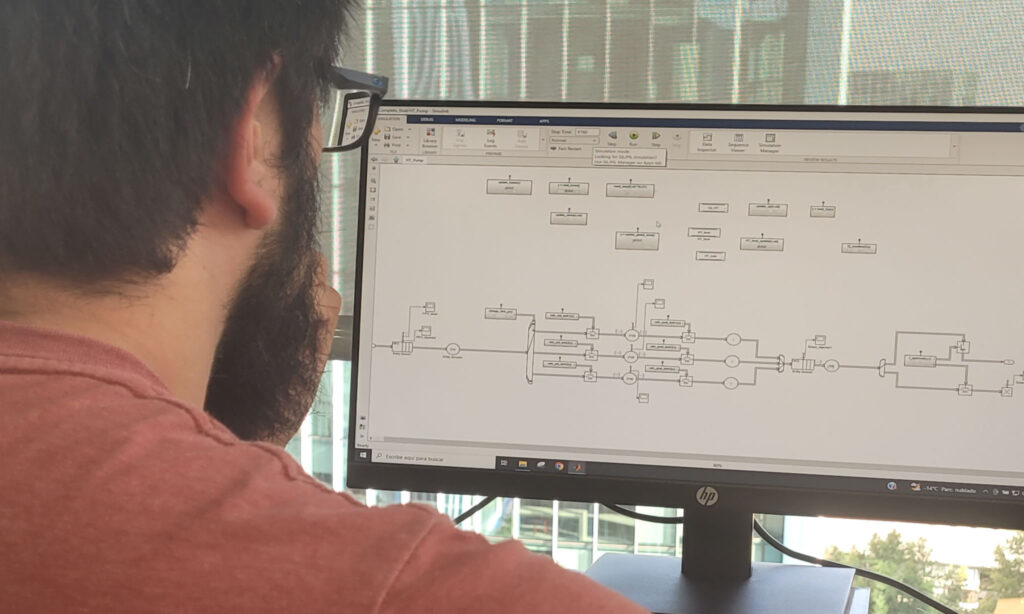

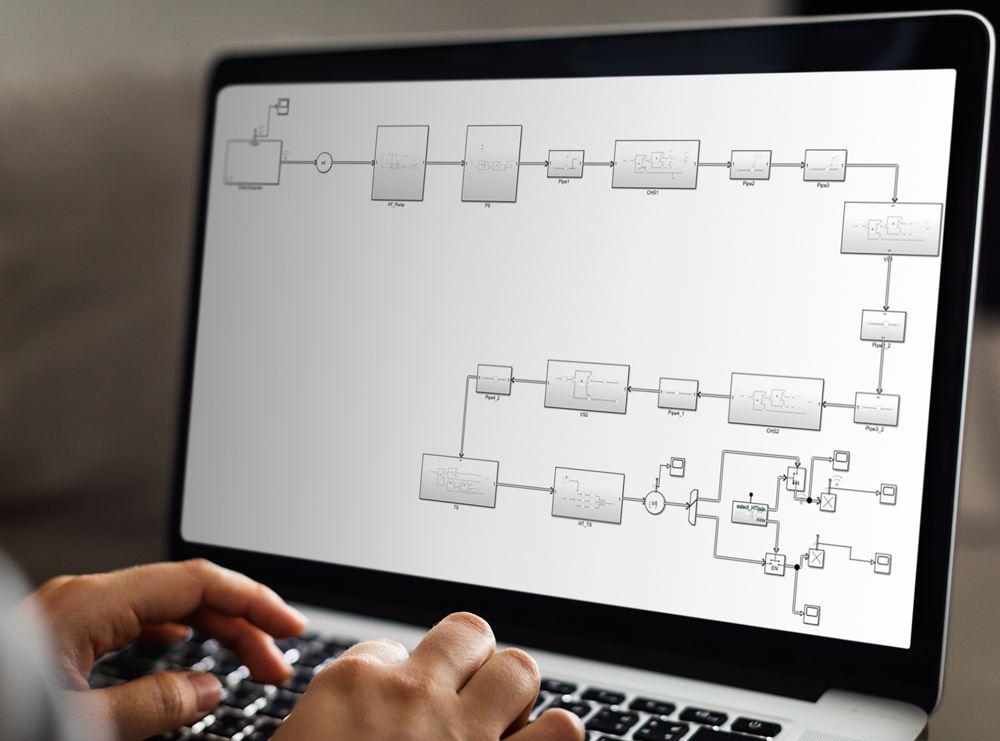

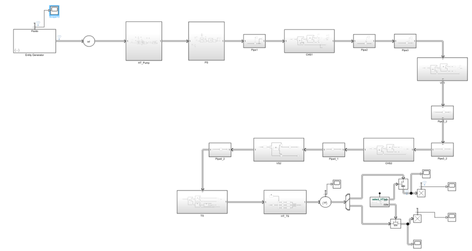

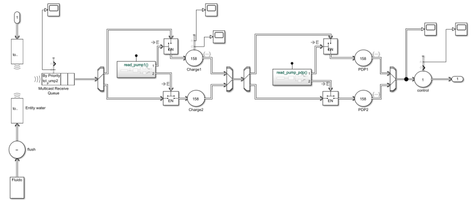

Currently, this software has been applied to perform comprehensive modeling of systems. Specifically, it has been used to model a concentrate pipeline starting from the thickener discharge outlet and extending to the filter plant inlet at the port (Fig.1), as well as the modeling of a positive displacement pump (Fig.2).

DISCOVER MORE

Get in touch with BRASS and learn about everything we can build together.