Technology / LDS – Leak Detection System

B-LDS® Leak Detection System

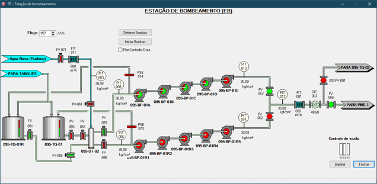

The purpose of the Leak Detection System is to quickly alert the control center about the occurrence of a leak, thus mitigating environmental and financial impacts that may affect organizational reputation. The system uses data parameters measured by existing sensors within the system (Pressure, Flow, Density, etc.)

BRASS

Expertise

BRASS has set the bar for leak detection in the fluid transport industry. The extensive experience gained over the last 20 years and the fine tuning of its technology are recognized in the market.

Direct Benefits

Exclusive Technology

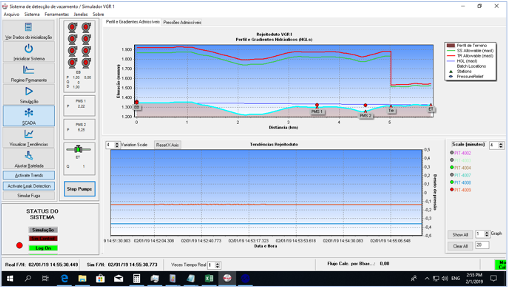

The BRASS Leak Detection System (B-LDS®) is based on an in-house developed program designed to operate continuously and uninterrupted. The program communicates leak alarms to the main control system (DCS) through an OPC server.

Leak detection methods

- Simulation of pressure transients (actual vs calculated variable).

- Analysis of pressure points, when the fluid transport system has anomalies.

Leak detection system performance

Sensitivity: Detection time vs detected flow

Reliability: Number of expected false alarms

Accuracy: Regarding gauging and pinpointing the exact location of the leak.

Our leak detection system has been implemented in various mining companies around the world

We are a company with extensive experience in pipeline integrity projects, reducing the likelihood of system failures through internal inspection and predictive maintenance systems.

[display-map id=’3826′]

Response time in test

PIPELINES UP TO ≈ 8 KM / ACCURACY <300 METERS

PIPELINES ≈ 150 KM / ACCURACY <600 METERS

B-LDS® Additional Functions